Dry ice blasting.

Sustainably clean any object, structure or machinery.

.

Dry Ice blasting is one of the most sustainable cleaning solutions available to a range of industries, and delivers a key component of the circular economy.

A multi award-winning Dry Ice blasting business, Eco is a fully qualified and SQA accredited company offering the highest level of Dry Ice cleaning service with 13 years of experience.

By keeping plants and equipment expertly maintained through a Dry Ice blasting programme, different industries are able to keep their facilities and environments working efficiently for longer, reducing costly downtime, increasing productivity and reducing the level of investment needed in new parts and equipment.

Dry Ice blasting, also known as cryogenic blasting, is the leading-edge

sustainable, environmentally-friendly

technology that uses dry ice to clean all types of surfaces and machinery.

This alternative to conventional methods of contaminant removal is an economical and environmentally friendly way to remove debris or contaminants from any object, structure or machinery.

Dry ice blasting is also extremely effective in removing the damage caused by fire and smoke.

With reduced downtime and a safer, cleaner, faster approach to cleaning, Eco Dry Ice blasting can be used where other methods are unsuitable such as on electrical machines and in the food industry and is the ideal solution for many industries and individuals.

We use only fresh high-density dry ice and state-of-the-art equipment. Our teams possess extensive expertise and experience in all sectors, specialising in industrial cleaning, decontamination, surface preparation, restoration, and disaster recovery.

Customer satisfaction is our high priority and we offer many different solutions. We cater for all industries including:

- Nuclear

- Paper and Packaging

- Rubber and Composite

- Food and Drink Manufacturing

- Conservation, Residential and Commercial buildings

- Printing

- Automotive

- Aerospace and Aviation

- Oil and Gas

- Power Generation

- Marine

- Fire Restoration

- Pigment Industry

- ... and many more.

We will meet your business needs.

Why choose

Eco Dry Ice

blasting?

-

environmentally friendly

Dry ice is an environmentally safe and effective alternative to current cleaning methods, approved even in the marine and food sectors.

-

increases productivity, reduces downtime & costs

Most applications can be easily cleaned in-situ, without the need for disassembly or concerns about trapping grit or leaving residue. This not only prevents hours of employee down-time, but also saves your business precious time and money.

-

prolongs lifespan of assets

Often overlooked, effective cleaning is a crucial component in the circular economy, prolonging the lifespan of plant and equipment through reliability-centred maintenance.

To ensure maximum lifespan and efficiency of an asset, it is essential to clean it in a manner that helps the asset to operate at its optimal level.

Abrasive cleaning methods weaken the surface of the asset over time, reducing its lifespan, and cleaning with chemicals or toxins not only poses potential damage to equipment and components, but also leaves undesirable moisture and residues on surfaces.

Traditional cleaning methods also increase the risk of cross-contamination of surfaces, as well as seepage into delicate electrical circuitry.

Moisture-free and non-abrasive Dry Ice cleaning helps extend the asset life and reliability of existing equipment.

-

non-abrasive, no damage

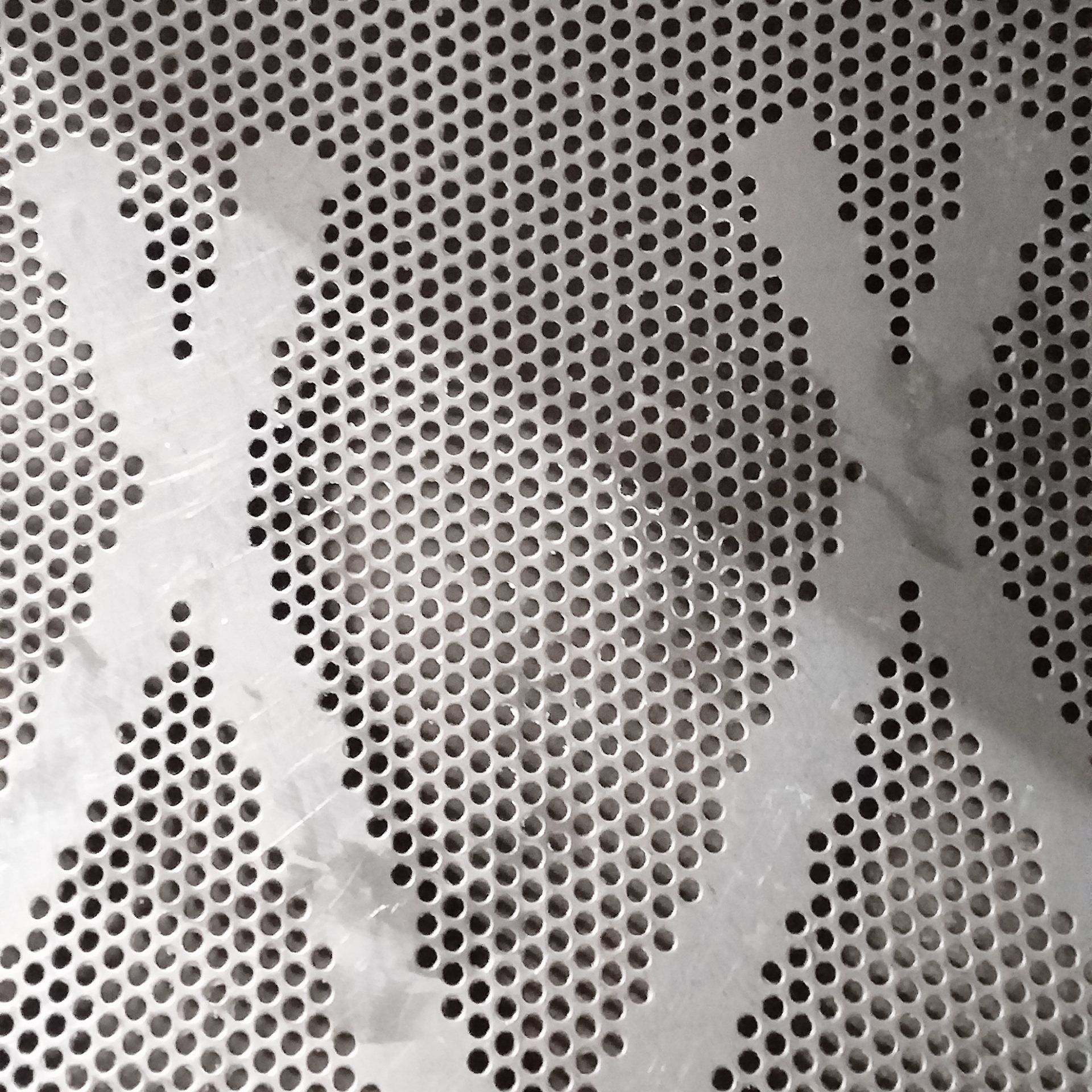

Dry Ice cleaning is a gentle and non-abrasive method that does not cause any scratching or roughness to materials. Blast pressure, ice rate, and nozzles are expertly adjusted ensuring the utmost care for even the most delicate applications.

-

moisture-free cleaning

Dry Ice cleaning is the most effective way to ensure there is no moisture created in the cleaning of your plant and equipment. This makes it an ideal, cost-effective and sustainable solution for cleaning different environments in a range of diverse industries.

-

faster and more efficient clean

With no need to disassemble machinery for cleaning, Dry Ice blasting saves time (and money).

The dry ice also reaches into spaces that other methods would struggle to clean.

With no residue generated, only the removed contaminant requires cleaning up, making the process much faster than traditional blasting.

-

no secondary waste / residue

Dry Ice sublimates completely to CO2. This means there are no residues such as waste water or abrasives, and reduces cross-contamination risk.

-

safe around electrical components

Dry Ice cleaning is a moisture-free solution for cleansing electrical equipment. By employing dry ice pellets as the blasting medium, they undergo sublimation upon contact with the surface, bypassing the liquid state and transitioning directly from solid to vapour.

This process effectively elevates contaminants from the targeted area. Notably, the residue-free nature of dry ice cleaning ensures less clean-up and reduced downtime.

Eco know that some industries struggle to have their equipment restored or decontaminated. Sometimes the only real way to have this done is to have the machinery taken off-site, which is time consuming and expensive – not with Dry Ice Blasting.

Dry Ice cleaning is rapidly gaining popularity due to several significant reasons that collectively contribute to the prolonged lifespan, enhanced reliability, and improved performance of existing equipment, and the gentleness of the process which leads to a damage-free free, fast clean with no residue.

Slide the arrows below to see some of the the dry ice cleaning successes we have had across many sectors.

How dry ice blasting works.

-

City skyline

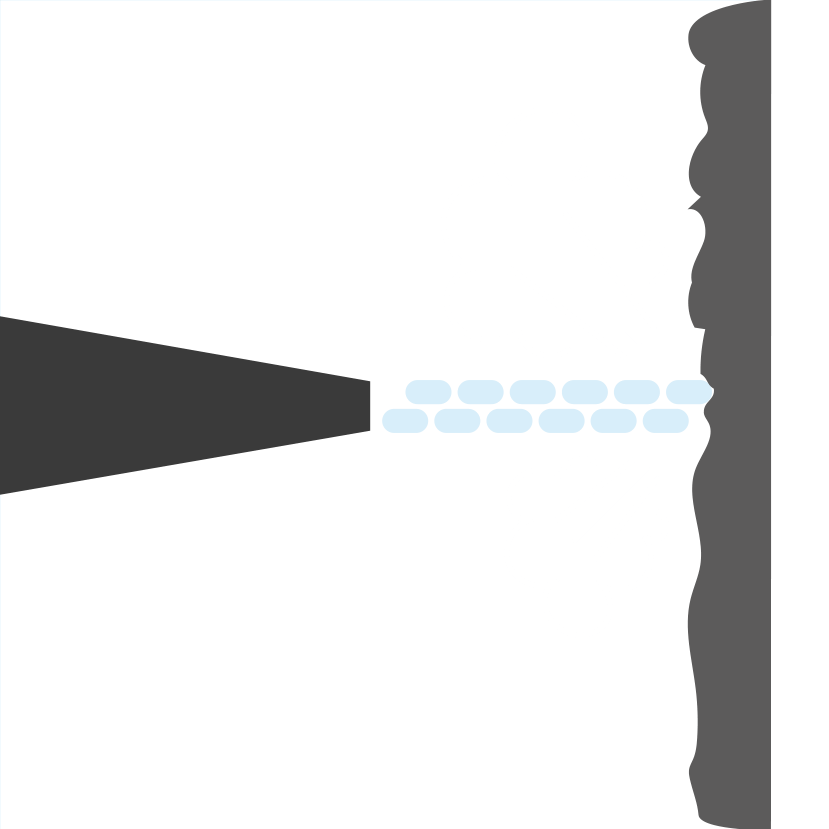

ButtonCompressed air pressure blasts dry ice pellets which sublimates on impact as carbon dioxide gas (CO2). Due to expansion, the contaminants are lifted and separated from the surface.

-

Birthday Sparks

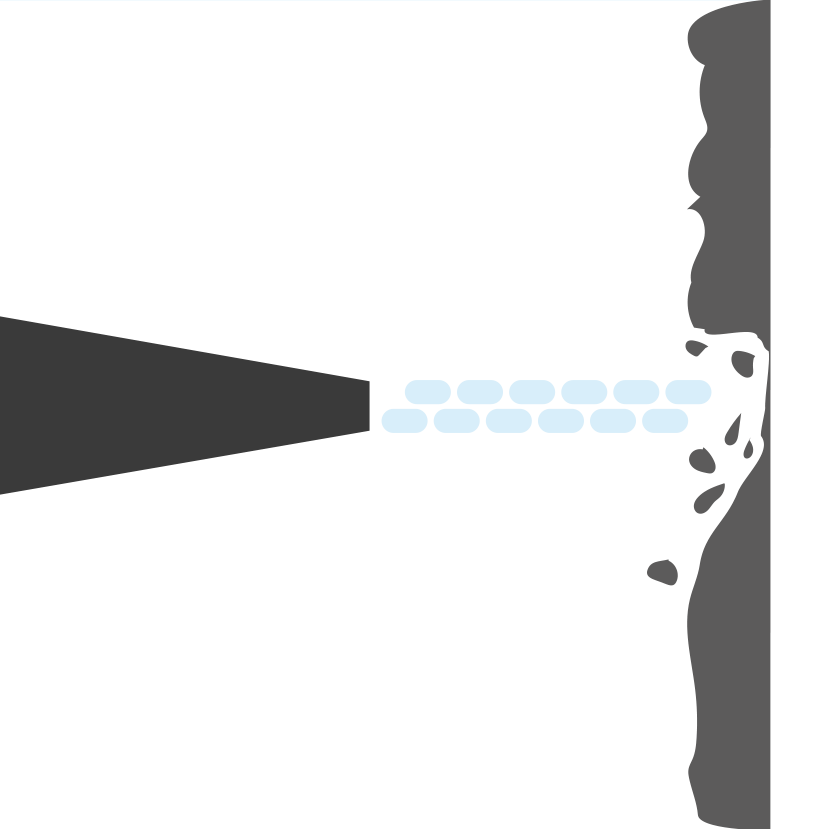

ButtonThe low temperature of the dry ice pellets (-78°C) causes the contamination to freeze, contract and crack resulting in the easy detachment of the contaminant from the surface.

-

Fashion Magazine

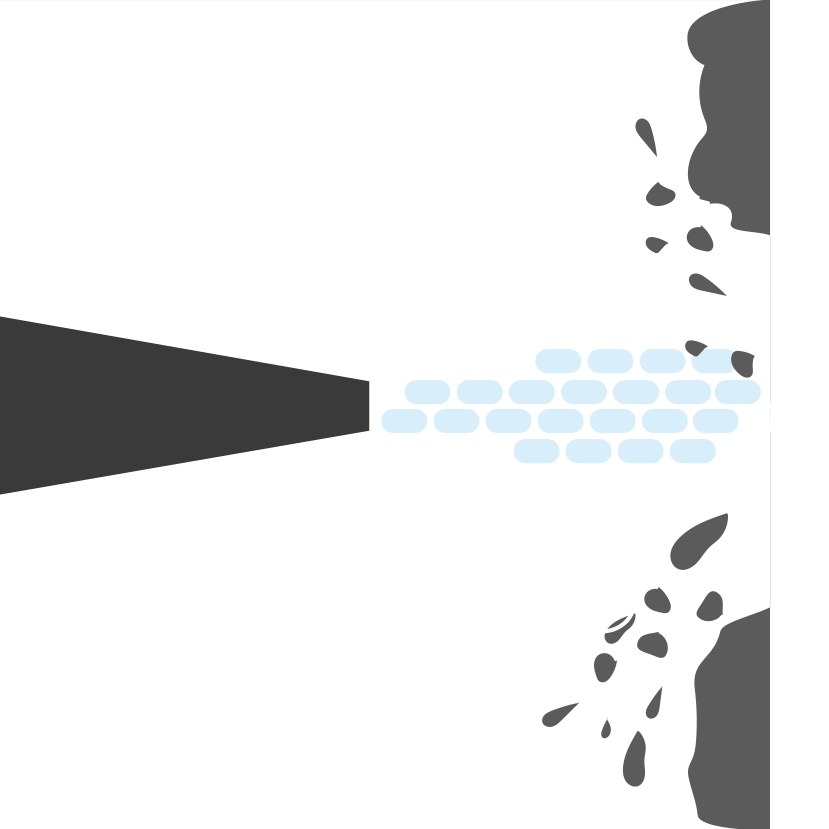

ButtonThe sublimation on impact means that only the original contaminant is removed.

-

Blurred Lines

ButtonUnlike other blasting techniques, dry ice blasting does not create any secondary waste because dry ice sublimates on contact.

Why choose

Eco Dry Ice

blasting?

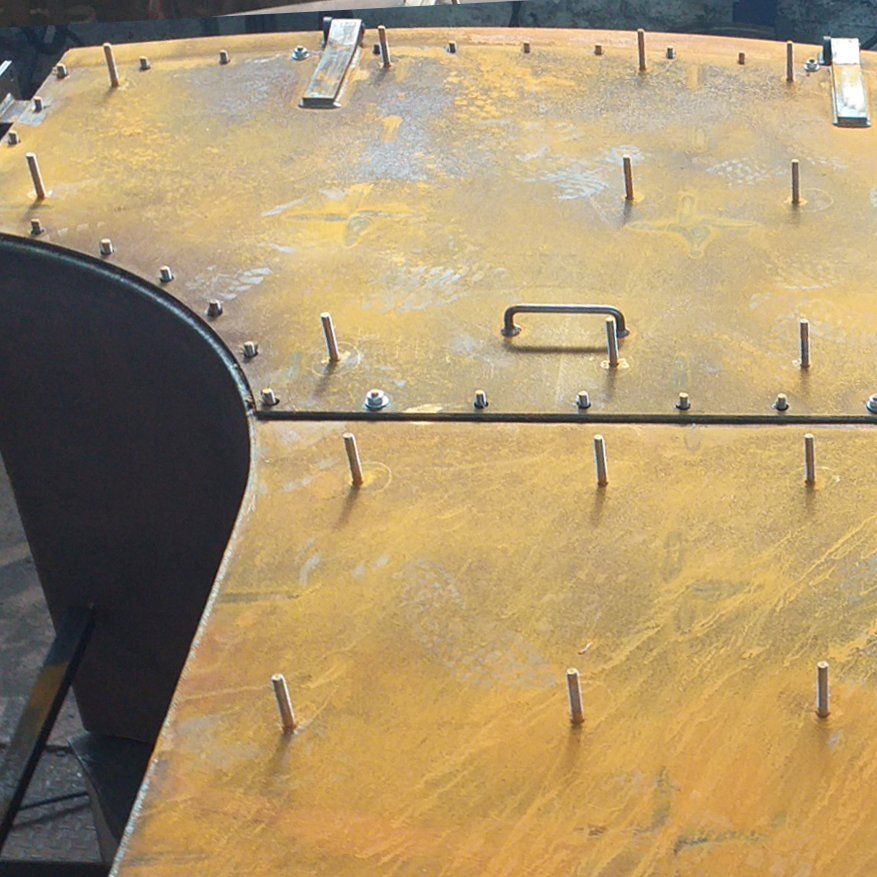

Rust removal

Vines on sandstone removal

Industrial laundry drum clean

Tiled floor and grout clean

Commercial kitchen grease clean

Commercial kitchen clean

Stone building vine removal

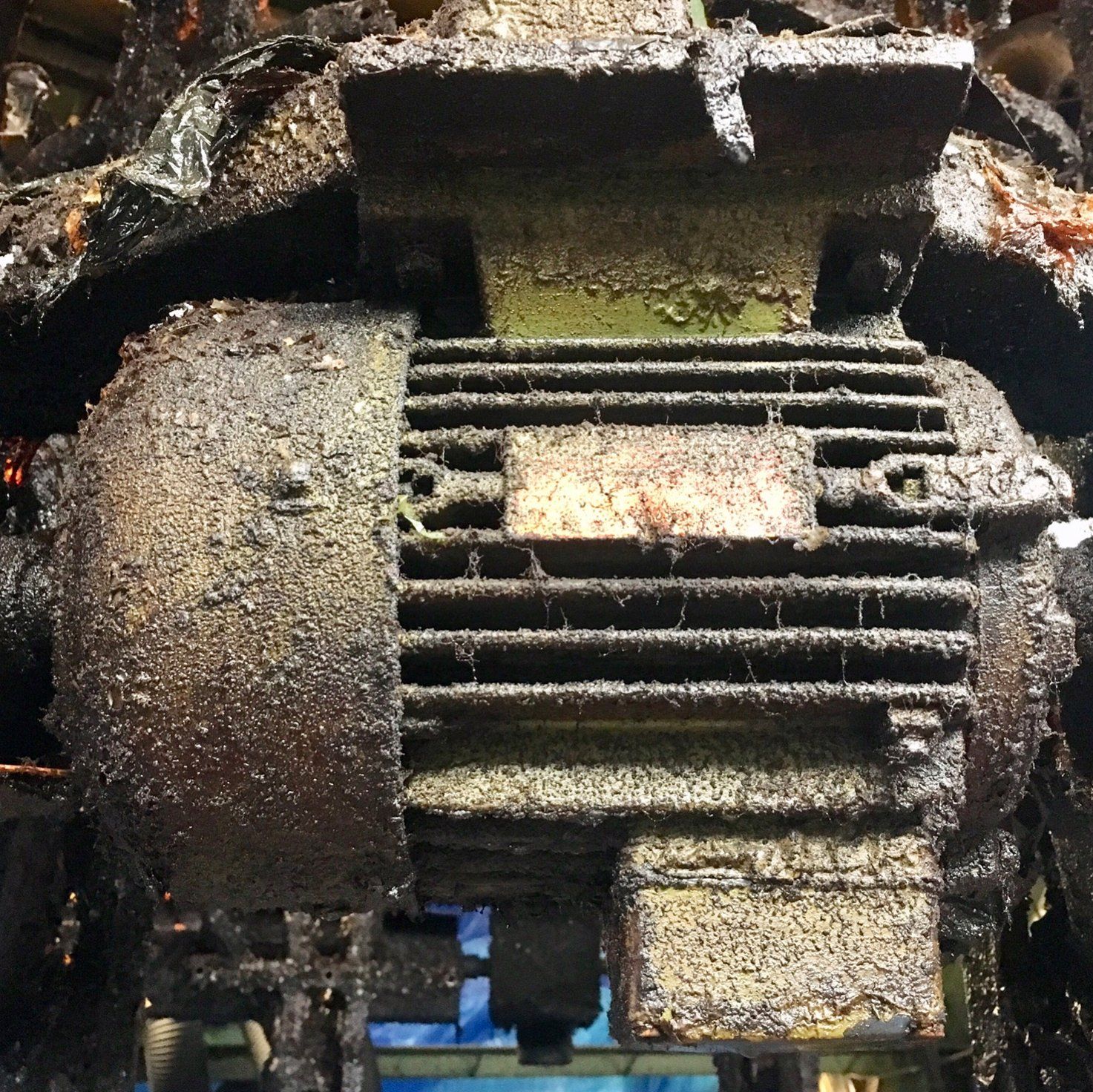

Industrial machinery grease and oil clean

Factory machinery grease and oil clean

Get in touch with the eco team.

We’d love to hear from you.

Just choose the most convenient method and we’ll get back to you as soon as we can.

ADDRESS: ECO GROUP HQ

6 ANNAN BUSINESS PARK WAY

ANNAN

DUMFRIESSHIRE DG12 6TZ

T : 01461 500 206

Contact Us

We will get back to you as soon as possible

Please try again later

Sign up to our newsletter

Contact Us

We will get back to you as soon as possible

Please try again later