Even if we had spent a month

on this we would not achieve the results

Eco did in several hours.

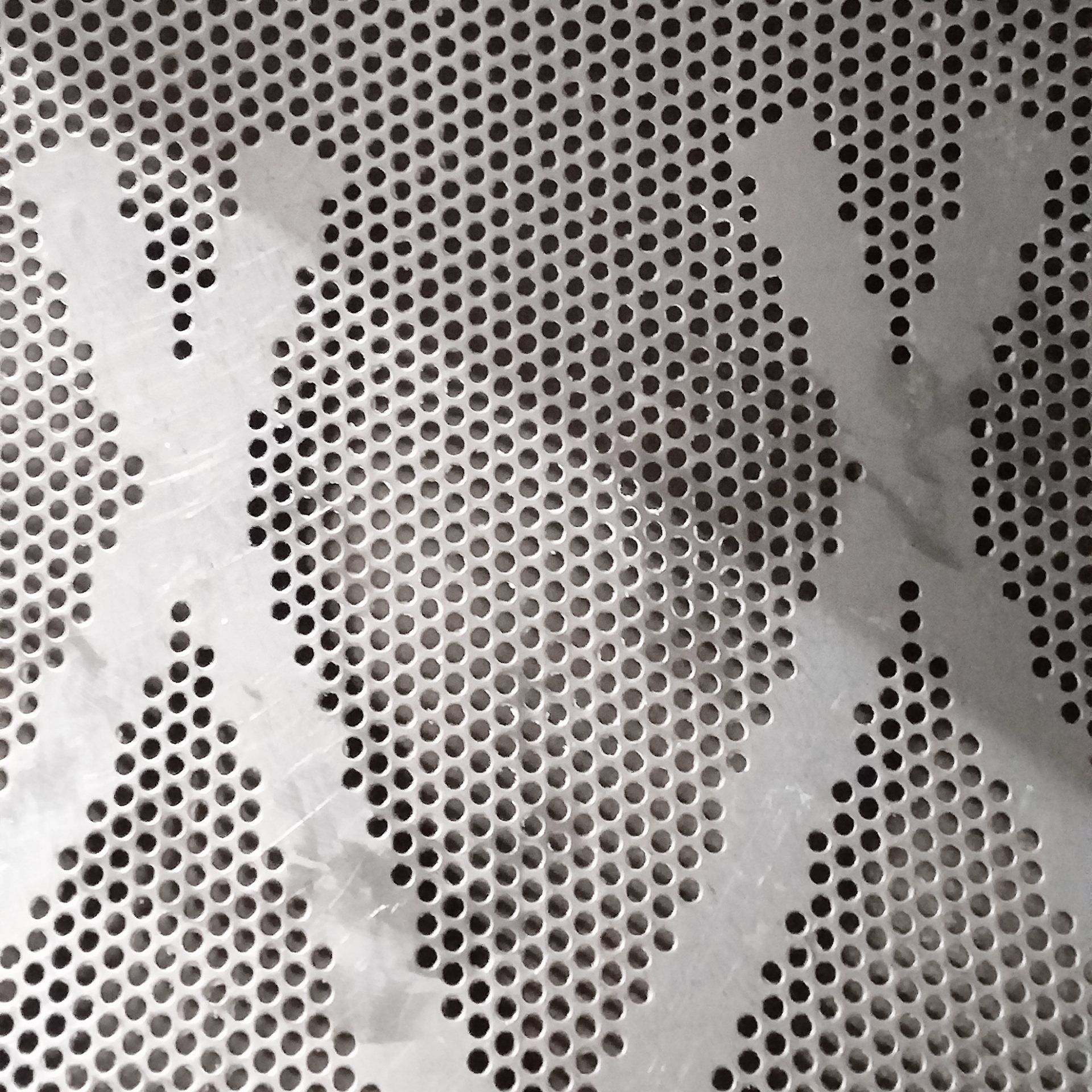

the problem

Laundry dryers require cleaning to eliminate contaminants and reinstate airflow to the products being dried without causing any damage to the surfaces or creating unnecessary downtime.

Dryer panels become heavily contaminated with foreign objects which affect the air flow and hinder the overall performance of the

dryers causing wet items having to be dried multiple times as they come out still damp.

CASE STUDY

Drying times were exceeding target of 20 minutes, and some garments required drying off-line, costing the business both time and money.

Client had spent hours grinding and chipping the oldest dyer - the 2003 Kannegiesser, without success.

- CL Lines

- 2 Jensen DT60s

- 2 Jensen DT90s

- Flat Linen Kannegiesser Dryer

the solution

Qualified dry ice cleaning to meet your business needs.

- NO RISK TO STAFF OR PRODUCT

- NON-ARBRASIVE

- GREEN CLEAN/ENVIRONMENTALLY FRIENDLY

- CLEANS FASTER AND MORE EFFICIENTLY

- CAN BE COMPLETED ON-SITE

- DOWNTIME DRAMATICALLY REDUCED

- PRODUCTION TIME INCREASED

- REDUCED COSTS

- PRODUCTIVITY AND APPEARANCE OF THE DRYERS ENHANCED

6 months on...

Within six months of cleaning we can see the contaminant build-up starting to block the airflow again.

With a three or six monthly maintenance plan we can keep on top of these dryers and have them running efficiently all year round every year.

GET IN TOUCH

With a three or six monthly maintenance plan we can keep on top of these dryers and have them running efficiently all year round every year.