Design and Build Solutions.

Our recycled glass solution is revolutionising the global construction industry.

.

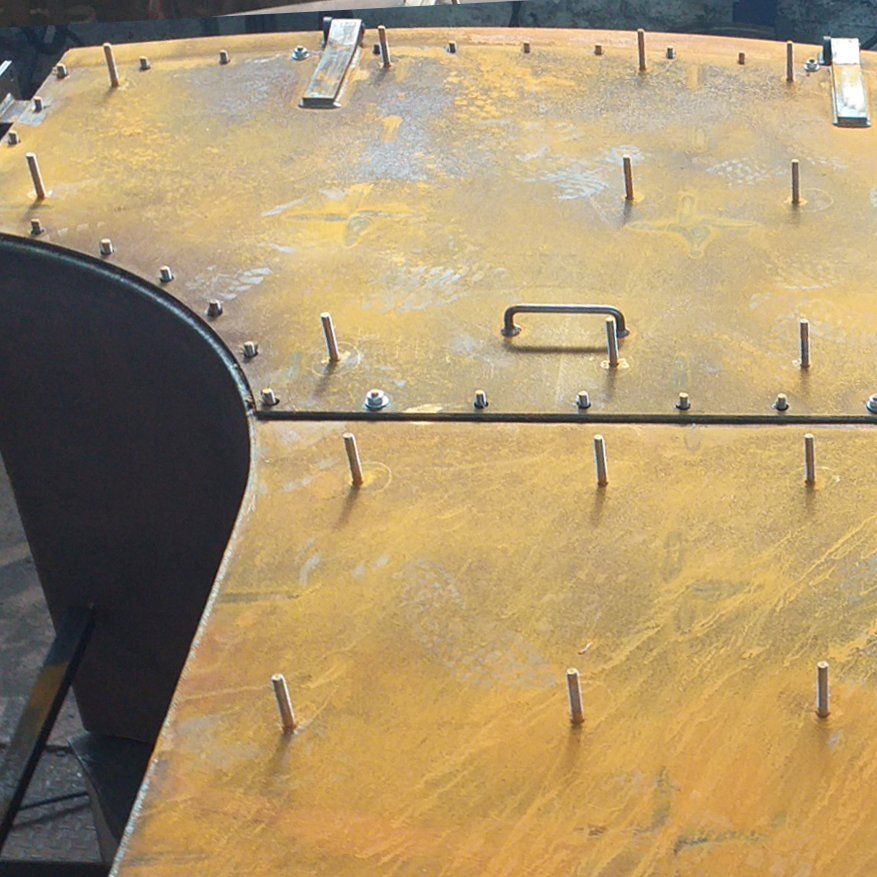

Our business will create buildings from panels manufactured from recycled glass.

This circular innovation will create a new build system and building modules with scalable manufacturing, positively disrupting the market and creating high growth potential.

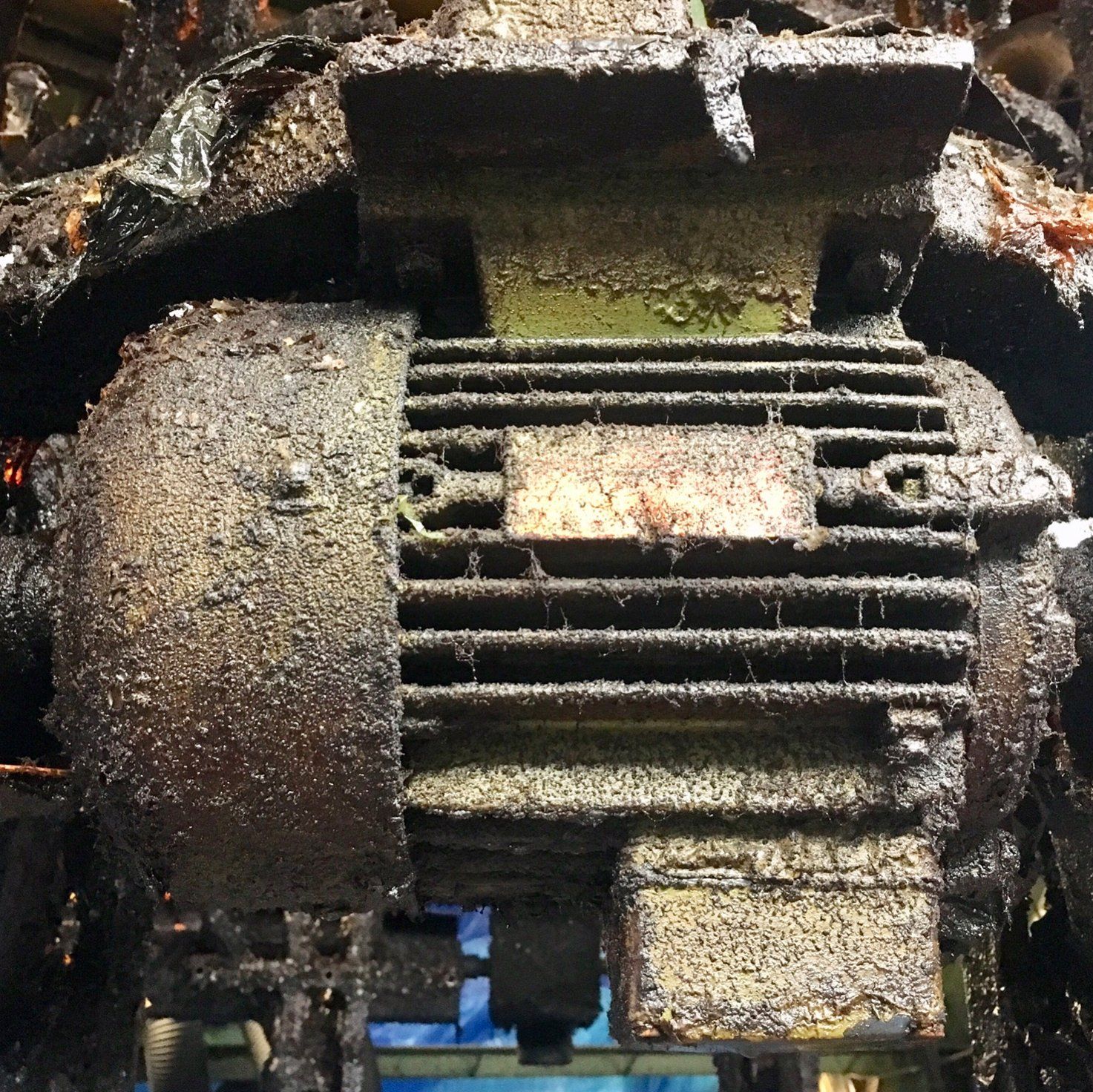

By keeping plants and equipment expertly maintained through a Dry Ice blasting programme, different industries are able to keep their facilities and environments working efficiently for longer, reducing costly downtime, increasing productivity and reducing the level of investment needed in new parts and equipment.

- Recycled glass in construction contributes to the circular economy concept, where materials are reused or recycled instead of being discarded.

- Building a house from recycled glass not only increases product durability, structural integrity and ultimately performance, but also demonstrates innovation and differentiation in the construction industry.

- A cost-effective alternative to traditional building materials while maintaining durability and structural integrity.

- A house made from recycled glass positions itself as a distinctive and environmentally conscious property, appealing initially to an early mover adoption market. Recycled glass can offer cost advantages in construction.

A time-lapse of

innovative materials

in home construction

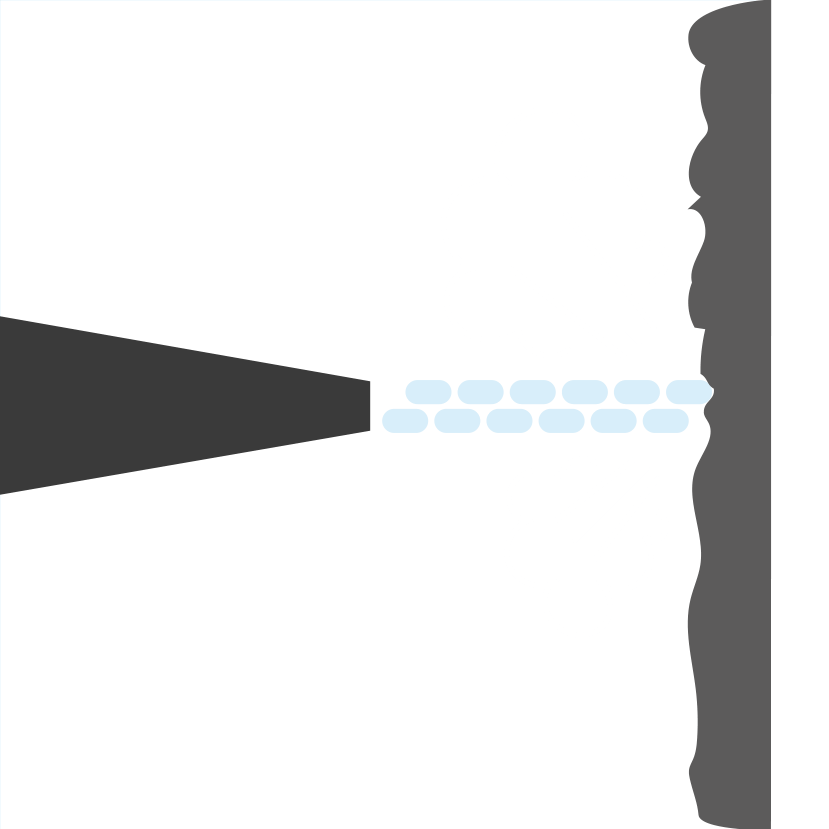

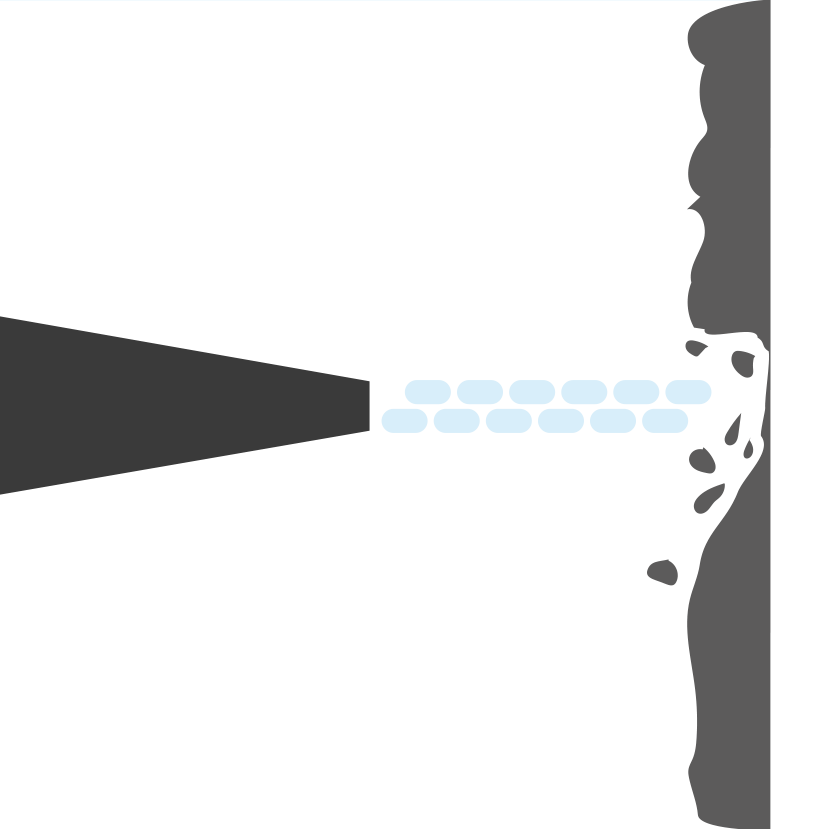

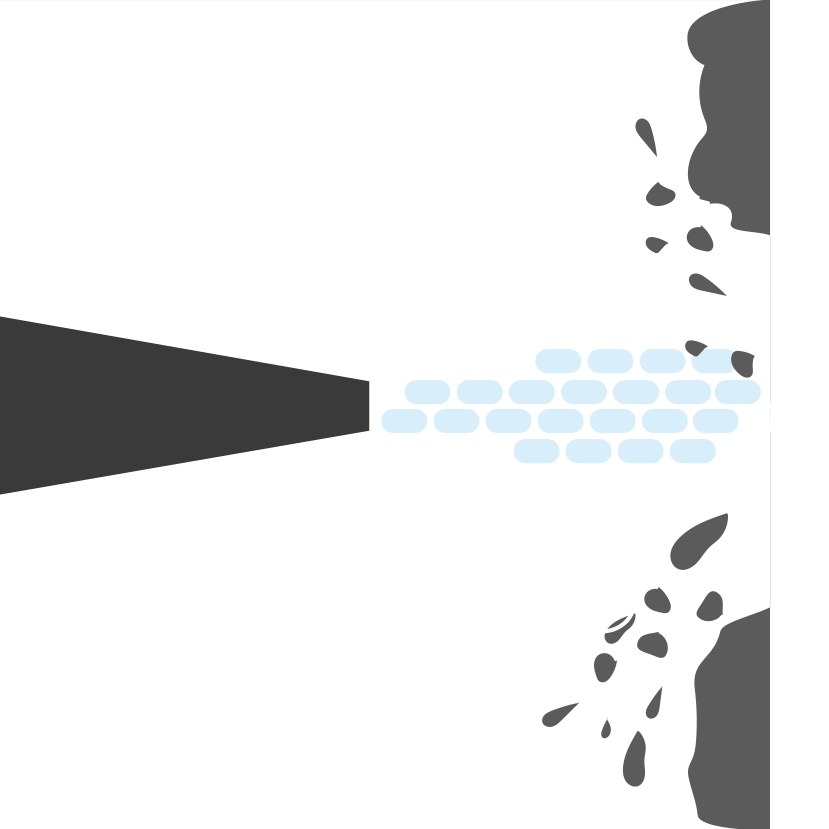

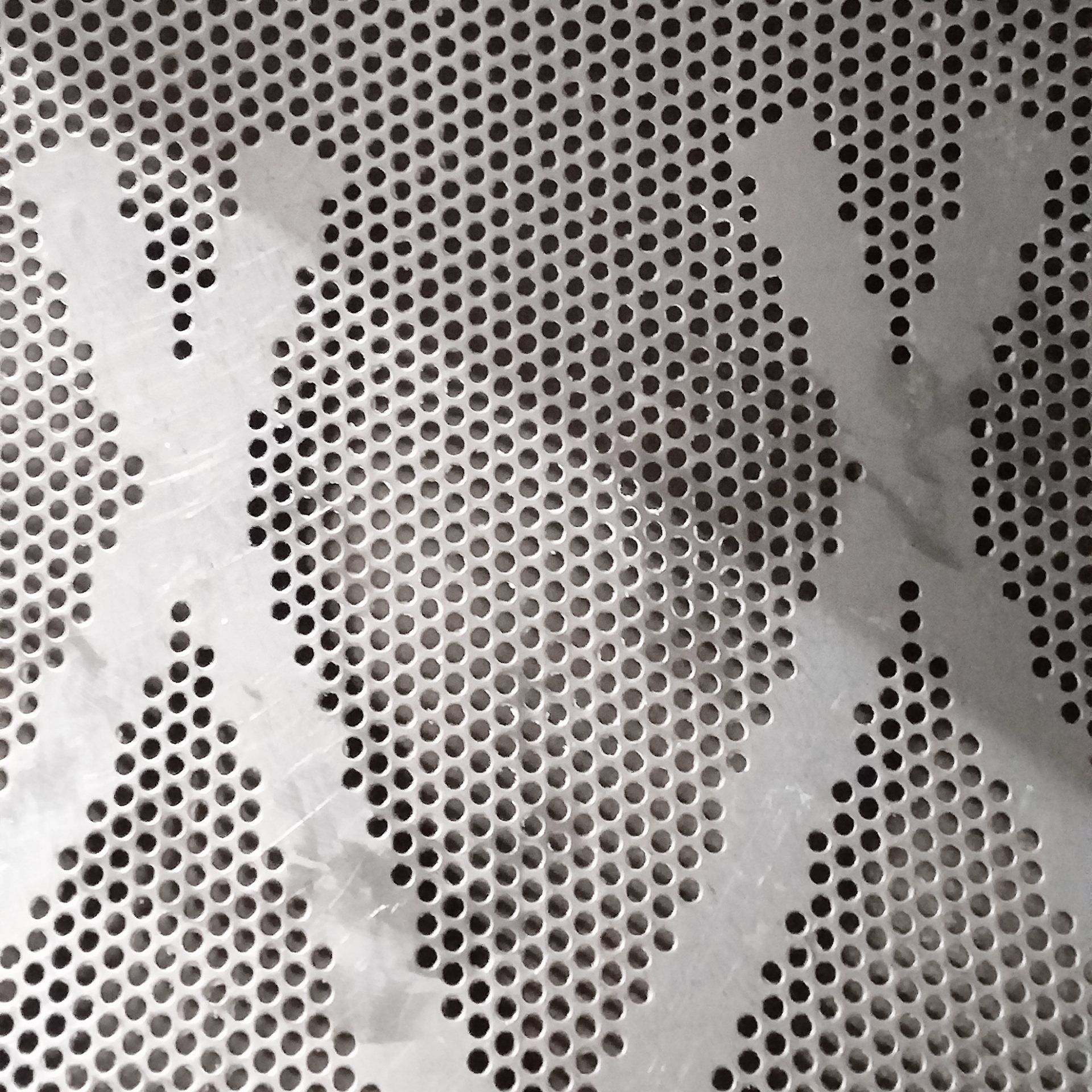

How dry ice blasting works.

City skyline

Compressed air pressure blasts dry ice pellets which sublimates on impact as carbon dioxide gas (CO2). Due to expansion, the contaminants are lifted and separated from the surface.

Birthday Sparks

The low temperature of the dry ice pellets (-78°C) causes the contamination to freeze, contract and crack resulting in the easy detachment of the contaminant from the surface.

Fashion Magazine

The sublimation on impact means that only the original contaminant is removed.

Blurred Lines

Unlike other blasting techniques, dry ice blasting does not create any secondary waste because dry ice sublimates on contact.

Why choose

Eco Dry Ice

blasting?

Rust removal

Vines on sandstone removal

Industrial laundry drum clean

Tiled floor and grout clean

Commercial kitchen grease clean

Commercial kitchen clean

Stone building vine removal

Industrial machinery grease and oil clean

Factory machinery grease and oil clean